Is tool and die maker a good career?

It’s true that tool and die making isn’t as well-known as some other trades, but that doesn’t mean it’s not a great career choice. The demand for skilled tool and die makers is high, and that means job security and good pay. You’ll need to be willing to put in the time and effort, but it’s definitely worth it.

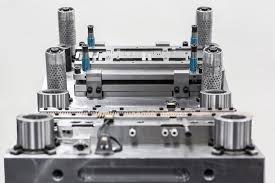

A tool and die maker is essentially a craftsman or craftswoman who creates the tools and dies used to make everything from car parts to medical devices. They use their knowledge of metals, machining, and engineering to create highly precise and complex tools.

What’s so great about tool and die making? Well, there are a number of things:

High earning potential: Tool and die makers are in high demand, which means they can command good salaries.

Job security: With the demand for skilled tool and die makers consistently high, jobs are plentiful.

Variety: You’ll be working on a variety of projects, which will keep your job interesting and challenging.

Creative outlet: Tool and die making is a creative profession. You’ll be using your skills and imagination to create something new.

Problem solving: Tool and die making requires you to think critically and solve problems.

If you’re looking for a rewarding career with good job security and a high earning potential, tool and die making might be the perfect fit for you. Just be prepared to work hard and get your hands dirty!

How much does a tool and die worker make in Ontario?

But keep in mind, that’s just an average. Your actual income will depend on a few factors:

Experience: The more experience you have, the more you’ll likely earn. It’s a trade where skills are valuable.

Location: Salaries can vary slightly depending on where you work in Ontario. Larger cities often have higher pay.

Company: Some companies pay more than others, and you might also find opportunities for overtime or bonuses.

It’s important to remember that this is just a starting point. It’s definitely worth researching specific companies to see what they offer. You can also check out job boards and salary websites to get a better understanding of the current market.

And don’t forget about the potential for growth in your career! Tool and die makers have plenty of opportunities for advancement, especially if you’re passionate about the work and continue to learn and develop your skills.

What is the difference between a tool maker and a die maker?

Toolmakers are the masterminds behind the creation of various tools used in manufacturing processes. They are highly skilled in machining, utilizing equipment like milling machines, jig grinders, and lathes to bring their designs to life. Their expertise spans a wide range of tools, from simple jigs and fixtures to complex cutting tools and molds.

Die makers, on the other hand, specialize in the creation of dies – these are specialized tools used to shape and form materials, particularly metals, through processes like stamping, punching, and drawing. Die makers are experts in designing, constructing, and maintaining dies, ensuring they meet the precise specifications required for high-quality production.

Essentially, die makers are toolmakers who possess a deep understanding of the intricacies involved in die design and manufacture. They work with materials like hardened steel to create dies that can withstand the rigorous demands of high-volume production.

Think of it this way: A toolmaker is like a general contractor, capable of building various structures. A die maker is a specialized contractor focusing solely on building structures for shaping and forming materials. Both roles are essential to ensuring efficient and precise manufacturing processes.

What do tool and die companies make?

These tools and dies are essential for a wide range of industries, including automotive, aerospace, electronics, and medical device manufacturing. They allow companies to produce high-quality, consistent products in large quantities. Tool and die makers are skilled craftspeople who use advanced technology and precision machinery to create these essential components.

Imagine a car part, like a door handle. Before a car manufacturer can make millions of these handles, they need a precise die to shape the metal into the right form. This die is made by tool and die makers, and it’s designed to produce the handle with the exact dimensions, curves, and details required.

Think of it like a cookie cutter. A cookie cutter gives your cookies the perfect shape. A die does the same thing for metal parts, but on a much larger scale!

Tool and die makers are crucial for the manufacturing process. They ensure that products are made to the highest standards, which is why they play such an important role in a wide range of industries.

Is it hard to become a tool and die maker?

Think of it as a journey with a clear destination: becoming a skilled journeyman tool and die maker. Most apprentices start by earning a degree or certificate from a vocational school, where they learn the fundamentals of the trade. This gives you a solid foundation before you dive into the practical side of things. Then, you’ll get real-world experience through an apprenticeship with an employer, where you’ll learn the tricks of the trade and develop your skills under the guidance of experienced professionals. This apprenticeship phase usually takes at least five years to complete.

It’s a bit like learning a musical instrument: you start with the basics, practice diligently, and eventually master the craft. The apprenticeship process is designed to equip you with the knowledge and skills needed to excel in this field. And believe me, the rewards are worth the effort!

Tool and die makers are highly sought-after professionals, making them an essential part of many industries. They are responsible for designing, building, and maintaining the tools and dies used in manufacturing processes. Think about the intricate parts of your smartphone, car, or computer. These were all likely created using tools and dies made by skilled tool and die makers.

So, while it does take time and effort to become a journeyman tool and die maker, the journey is rewarding and leads to a career with excellent job security and earning potential. If you have a passion for precision, problem-solving, and creating things with your hands, this could be the perfect career for you!

Are toolmakers in demand?

This means that despite a stable job market, there will be a steady demand for skilled machinists and tool and die makers. This is partly due to retirements and a need for workers with specialized skills. The demand for these workers often varies depending on the specific industry, with aerospace, automotive, and manufacturing being particularly active areas.

In addition to the projected openings, many machinists and tool and die makers find work in smaller companies that are not part of the national employment projections. These smaller companies often rely on experienced professionals to maintain their operations and may be more willing to hire skilled workers with a proven track record. So, while the overall employment growth may be slow, there are still many opportunities for toolmakers who are passionate about their craft and willing to put in the effort to develop their skills.

Are tool and die makers in demand in Canada?

There are several factors that contribute to this positive outlook. First, Canada’s manufacturing sector is experiencing growth, which means that there will be a need for more tool and die makers to create and maintain the tools and dies used in manufacturing. Second, the aging workforce means that many experienced tool and die makers are nearing retirement, creating a need for new workers to fill those positions. Finally, the increasing use of automation in manufacturing is actually leading to a higher demand for skilled tool and die makers who can design, program, and maintain automated systems.

In addition to the positive outlook in Ontario, the demand for tool and die makers is also strong across Canada. The Canadian government has identified tool and die making as a critical occupation, which means that it is considered essential to the Canadian economy. This designation leads to various support programs and initiatives aimed at attracting more people to the field.

If you are considering a career as a tool and die maker, now is a great time to start your journey. The job market is strong, and there are many opportunities to learn and grow in this rewarding profession.

How long does it take to become a tool and die maker in Ontario?

Alternatively, you can gain certification by accumulating over five years of work experience in the field alongside relevant education. This could include high school courses, college programs, or industry-specific training in tool and die making.

Let’s break down the apprenticeship program a bit further:

Apprenticeship Structure: In Ontario, tool and die making apprenticeships are structured with a strong focus on practical skills. You’ll spend a significant portion of your time working alongside experienced tool and die makers in a shop environment. This hands-on experience is crucial for developing the dexterity, precision, and problem-solving skills needed in the trade.

Classroom Learning: While you’re gaining practical experience, you’ll also be attending classes at a recognized trade school or college. These classes cover the theoretical aspects of tool and die making including:

Blueprint reading and interpretation

Metalworking techniques

Tool design and fabrication

Quality control and inspection

Safety protocols

Progressive Training: The apprenticeship program is designed to gradually increase your responsibilities and skills. You’ll start with basic tasks and move on to more complex projects as you gain proficiency. This progressive approach helps ensure that you’re well-prepared for the challenges of the trade.

Remember that even with the five-year work experience option, formal education is still encouraged. Whether you choose the apprenticeship route or the work experience path, dedication to learning and continuous skill development will be key to your success as a tool and die maker in Ontario.

How much do tool and die engineers make in Canada?

If you’re just starting out, you can expect to earn around $53,625 per year. But with experience, you can earn as much as $72,220 per year.

The salary for a tool and die maker can vary depending on a few factors. These include:

Location: Salaries in major cities like Toronto or Vancouver might be higher than in smaller towns or rural areas.

Experience: As you gain experience, your salary will naturally increase.

Company size: Larger companies often offer higher salaries and benefits.

Industry: Some industries, like aerospace or automotive, might pay higher wages than others.

If you’re looking for a career with good earning potential, tool and die making is a great option. You’ll have the chance to learn a skilled trade, work with your hands, and build a successful career. Plus, the demand for skilled tool and die makers is high in Canada, so you’ll have good job security.

See more here: How Much Does A Tool And Die Worker Make In Ontario? | Tool And Die Maker Wages

How much does a tool & die maker make?

Let’s break down some of the factors that can affect your salary:

Experience: As you gain experience, you’ll likely earn more. Starting out, you might make closer to the lower end of the range, but as you progress and become more skilled, you can expect to earn more.

Location: Where you live can also impact your salary. Cost of living and demand for Tool and Die Makers can vary from city to city. For example, you might earn a higher salary in a major metropolitan area compared to a smaller town.

Company: Different companies have different compensation structures. Some companies might pay more than others, depending on their industry, size, and financial health.

Education and Certifications: While a formal degree isn’t always required, some Tool and Die Makers choose to pursue certifications or associate degrees to enhance their skills and increase their earning potential.

Additional Skills: If you have specialized skills like CNC machining or CAD/CAM software, that can also increase your value to employers and potentially lead to a higher salary.

Tool and Die Makers are in high demand, especially as manufacturing continues to grow. It’s a skilled profession that offers opportunities for growth and career advancement. If you’re looking for a stable career with good earning potential, Tool and Die Making could be a great option for you.

What does a tool and die maker do?

Tool and die makers are skilled craftspeople who create the dies and cutting tools used in manufacturing. Dies are the molds used to shape metal parts, while cutting tools are used to cut and shape materials.

They start by analyzing specifications for the part to be made. Then, they use their knowledge of metalworking to select the right metal stock and layout the design. Next, they use various machine tools, like lathes, mills, and grinders, to shape the metal.

Finally, they fit and assemble the parts to create the die or cutting tool.

Their work is crucial for ensuring that manufactured products are made to the correct specifications.

A Closer Look at the Work of a Tool and Die Maker

Think of a tool and die maker as a master craftsman. They have a deep understanding of both metalworking and design. They use their skills to create tools that are vital to the manufacturing process.

Here are some examples of the work done by tool and die makers:

Creating the dies used to make car parts: You see those complex shapes in your car? The dies that shaped them were likely made by a tool and die maker. They used their knowledge of metalworking to ensure the dies were precise and durable.

Making cutting tools for aerospace components: High-performance aircraft require very precise components. Tool and die makers use their skills to create cutting tools that can make these components to extremely tight tolerances.

Designing and building jigs and fixtures: These are special tools that hold parts in place during manufacturing. Tool and die makers use their knowledge of design and metalworking to create jigs and fixtures that are both strong and accurate.

Tool and die makers are essential to the manufacturing process. They are the ones who create the tools that make it possible to produce high-quality products.

Can a machinist become a tool & die maker?

So how does this transition happen? Well, many machinists gain the skills and experience needed to become tool and die makers through on-the-job training and apprenticeships. These apprenticeships, usually sponsored by employers, provide hands-on learning and mentorship, allowing machinists to develop the specialized skills required for tool and die making. This journey involves a lot of learning and honing your skills, but it can lead to a rewarding and exciting career path in the field of tool and die making.

Let’s delve a little deeper into what makes this transition possible. Machinists already possess a strong understanding of machining processes, materials, and tolerances. These foundational skills are essential for tool and die making. They’re also adept at operating CNC machines, which are critical for creating complex dies and molds. A machinist’s experience with measuring tools and quality control procedures further strengthens their ability to transition into a tool and die making role. They can then focus on learning the intricacies of die design, mold construction, and the specialized techniques used in this field.

So, if you’re a machinist with a passion for precision and a desire to work with complex designs, becoming a tool and die maker is definitely within your reach. It’s a journey that builds upon your existing skills, leading you towards a rewarding career that involves creating the tools that shape our world.

How much does a machinist make a year?

While the overall employment growth for machinists and tool and die makers is projected to be slow, there are still plenty of job opportunities available. In fact, it is estimated that there will be about 38,200 openings for machinists and tool and die makers each year over the next decade.

This is good news for anyone considering a career in this field. The demand for skilled machinists is likely to remain steady, and there are plenty of opportunities to find a well-paying job.

A few factors that influence a machinist’s salary include:

Experience: As you gain more experience, you can expect to earn a higher salary.

Location: Salaries for machinists can vary depending on the location. Jobs in major metropolitan areas tend to pay more than jobs in rural areas.

Industry: The industry in which you work can also impact your salary. For example, machinists who work in the aerospace industry may earn more than those who work in the manufacturing industry.

Education and Training: While a high school diploma or equivalent is typically required for a machinist position, some employers prefer candidates with an associate’s degree in a related field, such as machining, manufacturing, or mechanical engineering.

Certifications: Earning certifications can also help you increase your earning potential. Some common certifications for machinists include Certified Manufacturing Technologist (CMfgT) and Certified Manufacturing Engineer (CMfgE).

Here are some additional insights into machinist salaries:

Entry-level machinists typically earn a salary in the range of $30,000 to $40,000 per year.

Experienced machinists can earn a salary in the range of $50,000 to $70,000 per year or more.

Top-earning machinists can earn salaries of $80,000 to $100,000 per year or more, depending on their experience, location, industry, and certifications.

If you are interested in a challenging and rewarding career in machining, there is plenty of opportunity to make a good living. With the right skills, training, and experience, you can build a successful career as a machinist.

See more new information: countrymusicstop.com

Tool And Die Maker Wages: What You Need To Know

As a tool and die maker, you’re a skilled craftsman who designs and builds the tools and dies used to manufacture a whole range of products, from car parts to electronics. And that skill is valuable! But how much does a tool and die maker actually earn?

Well, it depends on a few things, like your experience, location, and the industry you work in. We’ll dive into those details, but let’s start with the basics.

What is the average tool and die maker salary?

The average tool and die maker salary in the United States is around $55,000 per year, but that number can fluctuate based on those factors I mentioned. Let’s break down some of those factors and see how they impact your paycheck.

Experience

The more experience you have, the more you’re likely to earn. An entry-level tool and die maker might earn a salary in the $40,000 to $50,000 range. But a highly experienced tool and die maker with 10+ years of experience could see a salary closer to $70,000 or even higher.

Location

Tool and die maker wages can vary by location. For example, tool and die makers working in major metropolitan areas like New York City, Los Angeles, or Chicago tend to have higher salaries than those working in rural areas. That’s because the cost of living in those metropolitan areas is higher.

Industry

The industry you work in also plays a role in your salary. Tool and die makers working in high-demand industries, like the aerospace or automotive industries, tend to have higher salaries than those working in other industries.

Education

You don’t need a four-year college degree to be a tool and die maker, but you do need specialized training. You can get this training through a trade school, apprenticeship program, or community college. Having formal education can definitely help boost your earning potential.

Certifications

Another way to increase your earning potential is to get certified. Several organizations offer certifications for tool and die makers. For example, the American Society of Tool and Manufacturing Engineers (ASTME) offers a Certified Tool and Die Maker (CTDM) certification. Passing a certification exam shows employers that you have the skills and knowledge necessary to excel in the field.

Other Factors

In addition to these factors, other things can influence your salary, like:

Company size: Larger companies tend to offer higher salaries than smaller companies.

Union membership: If you’re a member of a union, you may have a higher salary than non-union workers.

Overtime pay: Many tool and die makers work overtime, which can significantly boost their earnings.

The Future of Tool and Die Maker Wages

The demand for skilled tool and die makers is expected to grow in the coming years. That’s because manufacturing is becoming more automated, and companies are looking for skilled professionals who can design and build the tools and dies needed for this new generation of manufacturing. So, if you’re thinking about a career in tool and die making, the future looks bright.

FAQs

#Q: How much does a tool and die maker make per hour?

A: The average hourly wage for a tool and die maker in the United States is around $26.50. However, that number can vary depending on factors like experience, location, and industry.

#Q: What are some of the best states for tool and die makers?

A: Some of the best states for tool and die makers include Michigan, Ohio, Illinois, Pennsylvania, and California. These states are home to a large number of manufacturing companies and have a high demand for skilled tool and die makers.

#Q: What are the benefits of being a tool and die maker?

A: There are many benefits to being a tool and die maker. Some of the key benefits include:

High demand: The demand for skilled tool and die makers is high, so you’re likely to find a job.

Good pay: Tool and die makers typically earn good salaries.

Job security: The manufacturing industry is relatively stable, so tool and die makers often have good job security.

Variety: Tool and die makers work on a variety of projects, so their work is never boring.

Opportunity for advancement: Tool and die makers can advance their careers by getting certifications or taking on management roles.

#Q: What are some of the challenges of being a tool and die maker?

A: There are also some challenges to being a tool and die maker. Some of the key challenges include:

Physical demands: Tool and die makers often work with heavy machinery and must be able to lift and carry heavy objects.

Long hours: Tool and die makers often work long hours, including overtime.

Safety concerns: Tool and die makers work with sharp tools and heavy machinery, so safety is a top priority.

Conclusion

So, there you have it, a breakdown of tool and die maker wages. It’s a great career path with good earning potential and solid job security. If you’re interested in a career that combines creativity, problem-solving, and technical skills, tool and die making might be the perfect fit for you.

Tool and Die Makers – U.S. Bureau of Labor Statistics

Geographic profile for Tool and Die Makers: States and areas with the highest published employment, location quotients, and wages for Tool and Die Makers are provided. For a list of all areas with employment in Tool and Die Makers, see the Create U.S. Bureau of Labor Statistics

Tool and Die Maker Hourly Pay in 2024 | PayScale

The average hourly pay for a Tool and Die Maker is $27.05 in 2024. Visit PayScale to research tool and die maker hourly pay by city, experience, skill, employer Payscale

Machinists and Tool and Die Makers – U.S. Bureau of

The median annual wage for tool and die makers was $61,490 in May 2023. The lowest 10 percent earned less than $40,560, and the highest 10 percent earned more than $81,720. In May 2023, the U.S. Bureau of Labor Statistics

How much does a Tool And Die Maker make in the United

The range for our most popular Tool And Die Maker positions (listed below) typically falls between $43,596 and $121,449. Keep in mind that salary ranges can vary widely Salary.com

Tool And Die Maker Salary (May 2024) – Zippia

Tool and die maker salaries typically range between $41,000 and $68,000 yearly. The average hourly rate for tool and die makers is $25.46 per hour. Tool and die Zippia

Salary: Tool And Die Maker in United States 2024 | Glassdoor

The average salary for a Tool And Die Maker is $74,109 per year in United States. Salaries estimates are based on 675 salaries submitted anonymously to Glassdoor

Tool and die maker salary ‐ CareerExplorer

Tool and die makers earn an average yearly salary of $37,278. Wages typically start from $24,589 and go up to $56,515. 41 % below national average Updated in 2023 CareerExplorer

Salary: Tool And Die Makers in United States 2024 | Glassdoor

Human Resources & Staffing. $64,242 / yr Total Pay. Confident. Glassdoor

Tool and Die Maker I Salary | Salary.com

The average Tool and Die Maker I salary in the United States is $64,506 as of May 28, 2024, but the range typically falls between $56,762 and $72,575. Salary ranges can Salary.com

Tool and Die Maker Salary | Salary.com

The base salary for Tool and Die Maker ranges from $62,817 to $79,047 with the average base salary of $71,002. The total cash compensation, which includes base, and annual Salary.com

Considering Careers: Tool \U0026 Die Maker Apprentice

Job Talks Oyap – Tool \U0026 Die Maker Apprentice

Job Talks – Tool And Die Maker – Randy Discusses Misconceptions Of The Job

Tool And Die Maker Jobs

Toolmakers Vs Machinists: What’S The Difference?

Link to this article: tool and die maker wages.

See more articles in the same category here: blog https://countrymusicstop.com/wiki