What is the reason for bracketing standard failure in HPLC?

Let’s break down why this happens and how you can troubleshoot it:

Imagine your standard solution is like a tiny bottle of perfume. When you open the bottle, the fragrance starts to disappear into the air. Similarly, when your HPLC standard is exposed to the air, the solvent it’s dissolved in can evaporate. This leaves behind a more concentrated solution, leading to inaccurate results.

Here’s how evaporation impacts your HPLC analysis:

Bracketing failure: Your standard solutions are designed to provide calibration points for your analysis. When the solvent evaporates, the concentration of your standard changes, causing the calibration points to shift. This can lead to “bracketing failure,” which means your samples cannot be accurately quantified.

Drifting peaks: You might observe your peaks drifting over time, making it harder to pinpoint the exact concentration of your analyte.

Poor reproducibility: Repeated injections might give you inconsistent results, making your data unreliable.

To prevent evaporation and ensure accurate results, consider these tips:

Store standards properly: Keep your standard solutions in a tightly sealed vial or container in a cool, dry place. This minimizes exposure to air and reduces evaporation.

Use a volatile solvent: If your standard is dissolved in a volatile solvent like methanol or acetonitrile, consider using a less volatile option like water.

Minimize exposure time: Only open the vial when you need to use the standard solution. Avoid leaving the vial open for extended periods.

Prepare fresh standards: If you’re experiencing frequent bracketing failures, consider preparing fresh standards more often. This ensures you’re working with a consistent and accurate concentration.

Use autosamplers: Autosamplers are great for minimizing the risk of evaporation. These automated systems handle your standards efficiently, reducing the time they are exposed to air.

By following these tips, you can significantly reduce the risk of solvent evaporation and ensure your HPLC results are accurate and reliable.

What is the bracketing standard in HPLC?

Think of it like this: Imagine you’re baking a cake. You carefully measure out all the ingredients, but the oven temperature fluctuates throughout the day. If you don’t check the oven temperature regularly, your cakes might turn out differently, even though you used the same recipe.

Bracketing Standards in HPLC work in a similar way. They help you monitor the consistency of your HPLC system’s performance over time. Here’s how it works:

At the beginning of your sample sequence: You run a Bracketing Standard (also called a Check Standard) with a known concentration.

After analyzing a certain number of samples: You run another Bracketing Standard. This helps you to identify any potential shifts in the system’s performance.

At the end of the sequence: You run another Bracketing Standard to confirm that the system’s performance has remained consistent.

Here’s why bracketing is important:

System drift: HPLC systems are sensitive, and small changes in temperature, pressure, or flow rate can affect the results. Bracketing Standards help you detect these drifts.

Calibration stability: The calibration curve used to determine the concentration of your samples is only valid for a certain period of time. Bracketing Standards ensure that your calibration remains accurate throughout the analysis.

Data reliability: By monitoring the system’s performance with Bracketing Standards, you can ensure that the data you obtain is reliable and accurate.

In conclusion, Bracketing Standards are an essential tool for ensuring the quality and reliability of your HPLC data. They help you to identify any potential problems with your system and ensure that your results are accurate and reliable.

What causes RSD failure in HPLC?

Priming your HPLC system before analysis is essential for accurate and reliable results. If you don’t properly prime the system, you can introduce air bubbles into the solvent lines. These air bubbles can cause fluctuations in flow rate, leading to variations in peak areas and, ultimately, an increase in %RSD.

Understanding the Impact of Air Bubbles

Air bubbles are like tiny traffic jams in your HPLC system. They disrupt the smooth flow of solvent and can interfere with the interaction between your sample and the stationary phase. This can lead to inconsistent peak heights, peak widths, and retention times.

Flow Rate Fluctuations: Air bubbles can compress and expand as they travel through the system, causing flow rate fluctuations. This variability in flow can affect the time it takes for your analyte to travel through the column, leading to variations in retention time.

Peak Area Variability: Air bubbles can also affect the efficiency of your column. As they move through the system, they can cause turbulence, which can disrupt the separation process. This can result in a broadening of peaks and a decrease in peak area.

Tips for Effective Priming

Use the Right Solvent: Start by choosing the appropriate solvent for your analysis. This solvent should be compatible with both your sample and the stationary phase of your column.

Purge the Lines: Before starting your analysis, thoroughly purge the solvent lines to remove any residual air. This can be achieved by running a blank injection of your chosen solvent.

Watch for Bubbles: As you purge the system, carefully observe the flow of solvent. Look for any signs of air bubbles, especially at the detector end of the system.

Prime the Pump: If your HPLC system is equipped with a pump, make sure it is properly primed. This involves ensuring that the pump head is full of solvent and that there are no air pockets within the pump itself.

Remember: By taking the time to properly prime your HPLC system, you’ll minimize the risk of air bubbles and ensure you get the accurate, reliable results you need.

What is the standard bracketing method?

But why do we need this bracketing method? Well, it helps us improve the accuracy and precision of our measurements. You see, there are always small variations in the instruments we use or the environment we’re working in. Bracketing helps us account for these variations and reduce their impact on our results.

Think of it like a balancing act. The low standard sets the lower limit of our measurement range, while the high standard sets the upper limit. The sample measurement then falls somewhere between these two standards. By bracketing, we create a reference point for our sample measurement, which allows us to get a more accurate reading.

Let’s take an example. Imagine you’re measuring the concentration of a chemical in a solution. The low standard might be a solution with a known low concentration, and the high standard might be a solution with a known high concentration. You then measure your sample. If the sample measurement falls closer to the low standard, you know its concentration is closer to the low standard value. Conversely, if it falls closer to the high standard, you know its concentration is closer to the high standard value.

So, the next time you’re working with measurements, keep the standard bracketing method in mind. It’s a simple but effective technique that can significantly improve the accuracy and precision of your results.

What is bracketing calibration?

Let’s break down what bracketing calibration is all about. Imagine you’re running a series of experiments using a high-performance liquid chromatography (HPLC) system. You’re injecting a standard solution of a specific compound at regular intervals throughout your experiment. As the experiment progresses, you might notice that the detector response to the standard is slowly decreasing. This could be due to a slight degradation of the detector over time.

Bracketing calibration addresses this issue by injecting a standard solution before and after your samples. By comparing the response of the standard before and after the samples, you can calculate a correction factor to compensate for the drift in detector response. This allows you to adjust your results to account for any changes in the detector’s sensitivity, ensuring that your data is accurate and reliable.

Here’s a more detailed explanation of the process:

1. Injection of the standard: You begin by injecting a standard solution of the analyte you’re interested in. This establishes a baseline response for your detector.

2. Injection of the samples: You then inject your samples, These samples might contain the analyte you’re interested in, or they might be blank samples for comparison.

3. Injection of the standard again: After injecting all your samples, you inject the standard solution again. This provides a second data point that allows you to compare the detector response at the beginning and end of your experiment.

Now, let’s say the detector response for the standard is slightly lower in the second injection compared to the first. This indicates a slight decrease in detector sensitivity. You can use this information to calculate a correction factor. This factor is used to adjust the responses obtained for your samples, accounting for the drift in detector response.

Bracketing calibration is a valuable technique for ensuring accurate and reliable results in analytical chemistry, especially when working with sensitive detectors or samples that might interact with the analytical system.

Why add TFA in HPLC?

Let’s dive a bit deeper into how TFA works as an ion-pairing reagent and why it’s so effective for separating biological molecules. The key lies in the unique properties of TFA. First, it’s a strong acid, meaning it readily releases a proton (H+). This proton can then interact with basic functional groups on the analyte molecules, such as amino groups in peptides or proteins. This interaction forms an ion pair, effectively neutralizing the charge of the analyte. The result is a change in its hydrophobicity, making it more “sticky” to the stationary phase and increasing its retention time.

The ability to control retention times through ion pairing with TFA is incredibly useful. In gradient elution, the composition of the mobile phase is gradually changed, typically by increasing the concentration of a more polar solvent. This allows for the sequential elution of different components in the sample, leading to better separation. TFA’s fast equilibration ensures that the change in mobile phase composition is effectively translated into changes in the interaction between the analytes and the stationary phase. This allows for a smooth and predictable gradient, resulting in sharper and well-defined peaks. In essence, TFA acts like a master conductor, orchestrating the precise separation of complex biological mixtures.

What is the principle of bracketing?

Imagine you’re watching a movie. You might be tempted to judge the characters, the plot, or the acting. But bracketing encourages you to step back and simply observe the events unfolding on the screen. You’re not trying to analyze or interpret anything, just to see what’s there.

This practice helps you to gain a deeper understanding of the experience by removing the filter of your own personal opinions and beliefs. It allows you to see the world in a fresh and unbiased way, opening up new possibilities for understanding and insight.

Think of it this way: When you put on a pair of glasses, you see the world through a lens. That lens shapes your perception. Bracketing is like taking off those glasses and seeing the world as it is, without any distortion.

Bracketing is a powerful technique for anyone who wants to understand the world around them more deeply. It’s a way to become more aware of your own biases and to develop a more open and receptive mind.

What is the standard sample bracketing method?

To understand how SSB works, imagine you are trying to measure the height of a building. You might use a measuring tape, but the tape itself could be slightly stretched or compressed, leading to inaccurate measurements. SSB works in a similar way.

The SSB method involves analyzing a standard with a known Si isotopic composition alongside the actual samples. This allows for the identification and correction of any instrumental mass discrimination that might be occurring. The analysis of the standard helps to calibrate the instrument, ensuring that the Si isotopic composition of the actual samples is measured accurately.

Think of the standard as a reference point. You can measure the height of the building with the tape, but then you use a known height of the standard to calibrate the tape, ensuring that future measurements are accurate. This is what SSB does for Si isotopic composition – it allows you to calibrate the instrument and obtain accurate results.

The SSB method requires that the instrumental conditions remain stable during the analysis of both the standard and the actual samples. This ensures that any changes in the instrument don’t affect the Si isotopic composition measurements.

By using SSB, scientists can obtain reliable and accurate Si isotopic composition data, which is crucial for various studies, including geochemistry, paleoclimate research, and understanding the processes that shape our planet.

See more here: What Is The Bracketing Standard In Hplc? | Bracketing Standard Failure In Hplc

Can %RSD failure cause bracketing failures in HPLC water systems?

You mentioned observing RT changes as the culprit behind your %RSD failures. This is a key clue. Retention time (RT) fluctuations can indeed cause %RSD issues, leading to bracketing failures.

Here’s a breakdown of why this happens and how to address it:

%RSD (Relative Standard Deviation) and Bracketing:%RSD measures the variability or precision of your analytical results. Bracketing involves running standards at the beginning and end of your analytical sequence. These bracketing standards establish acceptable limits for your results. If your sample results fall outside these limits (often due to %RSD issues), it triggers a bracketing failure.

RT Fluctuations and %RSD: When your RT drifts significantly, it impacts the accuracy of your peak integrations. This directly influences the calculation of your %RSD. Even slight RT shifts can cause substantial changes in your %RSD, leading to bracketing failures.

To tackle this, consider these preventive measures:

System Equilibration: Ensure your HPLC system is fully equilibrated before starting your analysis. This involves allowing enough time for the mobile phase and column temperature to stabilize.

Temperature Control: Precise temperature control is crucial. Fluctuations in column temperature can directly impact RT. Invest in a high-quality column oven or water bath for consistent temperature maintenance.

Mobile Phase Quality: Use high-quality, freshly prepared mobile phases. Air bubbles or contaminants in the mobile phase can disrupt flow patterns and affect RT.

Column Integrity: Inspect your column regularly for signs of wear or damage. A compromised column can lead to unpredictable RT shifts and %RSD issues.

Sample Preparation: Ensure your samples are well-prepared and consistent. Inconsistent sample preparation can contribute to RT variability.

System Maintenance: Regular maintenance of your HPLC system is essential. This includes cleaning the system, replacing worn parts, and checking for leaks or blockages.

Remember: Addressing the root cause of RT fluctuations will effectively combat your %RSD and bracketing failures. By implementing these preventive measures, you can ensure the precision and reliability of your HPLC analysis.

Is HPLC method development still a problem?

One of the most important criteria for a column is reproducibility of selectivity. This means that a column should consistently deliver the same separation results. Manufacturers work hard to ensure their production processes are robust and reliable.

Here’s why reproducibility of selectivity is so critical:

Consistent Results: Reproducibility guarantees that your method will consistently produce the same results. This is crucial for accurate analysis and reliable data. Imagine if a column gave different results each time you ran your sample! That would make it nearly impossible to draw accurate conclusions from your analysis.

Reliable Method Validation: Reproducibility of selectivity is fundamental for validating your HPLC method. Validation ensures that your method is accurate, precise, and reliable. You can’t validate a method that delivers inconsistent results.

Method Transfer: If you need to transfer your method to another lab or use a different instrument, reproducibility of selectivity makes this process seamless. You can be confident that the method will perform as expected regardless of the location or equipment.

While manufacturers make every effort to produce columns with consistent performance, factors like column packing and the properties of the stationary phase can sometimes introduce variations. These variations can impact the reproducibility of selectivity, even within the same batch of columns.

To minimize the impact of these potential variations, several practices can be implemented:

Pre-Column Conditioning: Before using a new column, it’s often recommended to condition it by running a series of solvents through it. This helps to stabilize the stationary phase and ensures that the column is ready for optimal performance.

Column Qualification: Before using a new column, it’s essential to qualify it to verify its performance. This involves running a test mixture and comparing the results to known standards. If the results are within an acceptable range, the column is deemed qualified and ready for use.

Column Storage: Proper storage of your column is critical. Storing columns in a clean, dry environment, away from direct sunlight and extreme temperatures, helps to maintain their performance.

By taking these steps, you can help to ensure the reproducibility of selectivity of your HPLC method, which is essential for generating accurate and reliable data.

What is system suitability in HPLC / GC?

System Suitability is a crucial aspect of HPLC (High-Performance Liquid Chromatography) and GC (Gas Chromatography) analysis. It’s like a “health check” for your analytical system, ensuring it’s working optimally to deliver accurate and reliable results.

Think of it this way: Imagine you’re baking a cake. You wouldn’t want to use a faulty oven or a broken measuring cup, right? Similarly, in HPLC and GC, we need to make sure our instruments are in tip-top shape to produce consistent and dependable data.

Bracketing Standards or Check Standards play a key role in this process. They act as “quality control” checkpoints throughout your analysis, helping to identify any potential issues with the system during a long sequence of samples.

Here’s how they work:

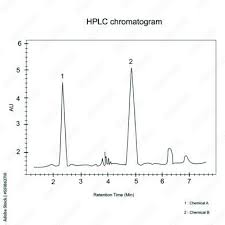

Bracketing Standards: These are reference standards run at the beginning and end of a sample sequence. They provide a baseline for comparison, revealing any shifts in retention times or peak areas that might occur during the analysis.

Check Standards: These are injected periodically throughout the sequence, typically after a certain number of samples. They act as “internal controls” to monitor any potential drift or changes in the system’s performance.

Why are these standards important?

Long Runtimes and Large Sample Sequences: In longer runs with many samples, it’s more likely for conditions to fluctuate. The flow rate might change, the column temperature may drift, or the detector sensitivity could fluctuate. These subtle changes can affect your results, making them less accurate.

Early Detection of Issues: By using bracketing and check standards, you can quickly identify these changes and address them before they significantly impact your analysis. This helps ensure the quality and reliability of your data.

Let’s break it down with an analogy:

Imagine you’re driving a car on a long road trip. You wouldn’t just drive without checking the tire pressure or fuel levels, right? Similarly, in HPLC and GC, using bracketing and check standards allows you to “monitor” your system’s performance throughout the analysis, ensuring consistent and reliable results, just like regularly checking your car ensures a safe and smooth journey.

How to fix HPLC problems?

The most important rule to remember is one change at a time. Think of it like a scientific experiment – if you change multiple things, you won’t be able to tell what caused the change, right? So, focus on changing just one thing at a time, then observe the results. This helps you identify the root cause of the problem.

Imagine you’re troubleshooting a peak shape issue. Instead of randomly tweaking the flow rate, the injection volume, and the column temperature all at once, you’d systematically test each parameter individually. For example, start by changing just the flow rate, keeping everything else constant. If the peak shape doesn’t improve, then you can move on to changing the injection volume, and so on.

By taking this methodical approach, you’ll be able to pinpoint the exact factor causing the issue and make the necessary adjustments to get your HPLC system back on track. This will save you time, frustration, and maybe even a little bit of your sanity. Remember, troubleshooting HPLC problems is like solving a puzzle, and following one change at a time is your key to finding the solution.

See more new information: countrymusicstop.com

Bracketing Standard Failure In Hplc: Causes And Solutions

Hey there! We’ve all been there, right? You’re running your HPLC, everything seems to be working smoothly, and then BAM! Your bracketing standard fails. It’s frustrating, but don’t worry, it happens to the best of us.

This guide is here to help you navigate the murky waters of bracketing standard failure and get back to your analysis.

Understanding Bracketing Standards: The Basics

Before we dive into troubleshooting, let’s quickly review what bracketing standards are and why they’re so important.

Essentially, bracketing standards are solutions run at the beginning and end of your HPLC run. These standards act as “bookends” for your samples, ensuring that your system is performing consistently throughout the entire analysis.

Think of it like this: if your bracketing standards show good peak shapes and retention times, you can be confident that the samples you ran in between are also reliable.

But what happens when your bracketing standards fail?

Causes of Bracketing Standard Failure

The good news is that bracketing standard failure isn’t always a sign of a major problem. Often, it’s something simple that can be easily fixed.

Here are some of the most common culprits:

Degradation of standards: The most obvious reason for bracketing standard failure is degradation of the standards themselves. Standards, especially those in solution, can degrade over time, especially if not stored properly.

Injection volume inconsistency: If your injection volume isn’t consistent, your bracketing standards might show different peak areas.

System issues: Leaks, blockages, or issues with the pump or detector can all affect your bracketing standards.

Temperature fluctuations: Changes in temperature can impact your system’s performance and result in bracketing standard failure.

Mobile phase issues: If your mobile phase isn’t fresh, degassed, or properly mixed, it can lead to inconsistencies in your results.

How to Troubleshoot Bracketing Standard Failure

Once you’ve identified the potential causes, it’s time to troubleshoot! Here’s a step-by-step guide to help you get back on track:

1. Check the standards: Make sure your bracketing standards are fresh, stored properly, and free from degradation.

2. Verify injection volume: Double-check your injection volume and make sure it’s consistent across all injections.

3. Examine the system: Look for any leaks, blockages, or signs of wear and tear in your system.

4. Monitor temperature: Ensure your system is operating at the correct temperature and that there are no fluctuations.

5. Analyze the mobile phase: Ensure your mobile phase is fresh, degassed, and properly mixed.

6. Run a system suitability test: A system suitability test is a good way to assess your system’s performance before starting your analysis.

7. Document your observations: Keep detailed notes of your troubleshooting steps and any changes you make. This will help you identify the root cause of the problem and prevent it from happening again.

Preventing Future Bracketing Standard Failure

The best way to deal with bracketing standard failure is to prevent it in the first place! Here are some tips:

Proper storage: Store your standards according to manufacturer’s instructions.

Regular maintenance: Schedule regular maintenance on your HPLC system to prevent problems from developing.

Quality control: Use a system suitability test before each analysis to ensure your system is performing correctly.

Good documentation: Maintain thorough documentation of your methods, standards, and troubleshooting steps.

FAQs

Q: How often should I run bracketing standards?

A: Ideally, you should run bracketing standards before and after each analytical run.

Q: What should I do if my bracketing standard fails, and I have already run my samples?

A: If your bracketing standards fail, and you’ve already run your samples, it’s best to re-run the samples once the issue is resolved.

Q: Can I use the same bracketing standards for multiple runs?

A: It’s generally not recommended to use the same bracketing standards for multiple runs, especially if your analysis is lengthy.

Q: What are some common causes of standard degradation?

A:Standard degradation can be caused by factors such as:

* Exposure to light: Many standards are sensitive to light.

Temperature fluctuations: Extreme temperatures can accelerate degradation.

Improper storage: Not storing standards properly can lead to degradation.

Contamination: Contamination from other chemicals or microorganisms can degrade standards.

Q: How can I tell if my standards are degraded?

A: Signs of standard degradation include:

* Change in color: A change in color may indicate degradation.

Precipitate formation: If you see precipitate forming in your standard solution, it’s a sign of degradation.

Reduced peak area: If you see a significant decrease in peak area compared to previous runs, it may indicate standard degradation.

Change in retention time: A change in retention time can also indicate degradation.

Q: What is a system suitability test?

A: A system suitability test (SST) is a set of tests performed before each analytical run to assess the performance of your HPLC system. It helps ensure that the system is operating within acceptable parameters and provides reliable results.

Q: What are some examples of system suitability parameters?

A: Common system suitability parameters include:

Peak area or height: Measured for a specific analyte to evaluate the sensitivity of the system.

Retention time: Measured for a specific analyte to evaluate the reproducibility of the system.

Peak resolution: Measured between two closely eluting peaks to evaluate the system’s ability to separate components.

Plate number: Measured for a specific analyte to evaluate the efficiency of the column.

Tailing factor: Measured for a specific analyte to evaluate the symmetry of the peak.

Q: What should I do if my system suitability test fails?

A: If your system suitability test fails, you should troubleshoot the system before proceeding with your analysis.

Remember, troubleshooting bracketing standard failure is about being systematic and persistent. By following these tips and understanding the underlying causes, you’ll be well on your way to achieving reliable and reproducible results!

Bracketing standard failure in long run — Waters Forums

Most likely, the cause is evaporation of your standard’s solvent. Assuming you do not have a chilled sample compartment, nor better cap liners available, the most likely solution is to use each standard vial for consecutive injections only, then not return to that vial once Waters Forum

Bracketing standard concept – Pharmaguideline Forum

The purpose of “Bracketing Standards” or “Check Standards”: Bracketed Calibration. There are times when the HPLC / GC conditions can change during a pharmaguideline.com

%RSD Failing issues — Waters Forums

Dear team, I am facing %RSD failing problems in HPLC waters systems which leads to bracketing failures. Can u guide me what precautions need to take before to start of Waters Forum

Final TIPS and Tricks HPLC Troubleshooting (2) – Agilent

Pressure Issues. Page 6. Determining the Cause and Correcting High Back Pressure. 窶「 Check pressure with/without column – many pressure problems are due to blockages in Agilent

Bracketing standard failures — Waters Forums

One of my bracketing standard injections has failed in the middle of the run, but all other brackets after this failure have passed specification. Should I invalidate all samples Waters Forum

HPLC Troubleshooting Guide

6 www.ace-hplc.com Introduction This troubleshooting guide contains examples of some of the most common problems observed in reversed-phase HPLC (RP-HPLC) HPLC

%CV between Bracketing Standards – Chromatography Forum

I am currently having problems with high %CV in bracketing standards on Waters 2495 & 2489. I make up my Standard and carry out two injections from one vial Chromatography Forum

Bracketing, a simple loading technique that increases

Abstract. A simple loading technique is described for high-performance liquid chromatography that permits almost quantitative sample transfer and recovery, improves ScienceDirect

HPLC Troubleshooting Guide – MilliporeSigma

Correct common HPLC issues to restore column performance, addressing peak problems, retention time, noise, and resolution with chromatograms. MilliporeSigma

How To Deal With Oos Test Results If System Suitability Is Failing

System Suitability Parameters Of Hplc | Resolution | Retention Time | Tailing | System Suitability

How To Use Bracketing Design For Stability Testing?

Lc Troubleshooting | Retention Time Shift | 5 Most Common Causes To Change In Retention Time In Hplc

What Is Covering Standard In Hplc | Hplc Analysis | Hindi

Link to this article: bracketing standard failure in hplc.

See more articles in the same category here: blog https://countrymusicstop.com/wiki