What is the difference between holographic grating and ruled grating?

Ruled gratings are traditional, and their grooves are created by a physical, mechanical process. The grooves are typically parallel to each other, and they can be found on both flat (planar) and curved (concave) surfaces.

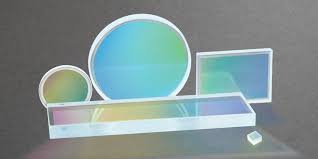

Holographic gratings, on the other hand, are formed through a more sophisticated process, using interference patterns created by laser beams. This allows for greater flexibility in groove design. These grooves can be parallel or vary in their distribution, depending on the specific needs of the optical system they are used in. Holographic gratings can be fabricated on various surfaces, including planar, spherical, and toroidal ones.

The key difference lies in their manufacturing methods and the resulting groove patterns. Ruled gratings are created by physically ruling lines into a material, while holographic gratings are formed by the interference of laser light. This fundamental difference leads to distinct characteristics in each type.

Ruled gratings tend to be less expensive and easier to manufacture, making them suitable for general-purpose applications. They are typically used in instruments like spectrometers and monochromators.

Holographic gratings are more expensive to produce, but their advanced capabilities make them desirable for applications requiring high precision and efficiency. They offer a broader range of groove designs, allowing for tailored performance based on specific needs. These designs can be optimized for high resolution, low stray light, or specific wavelength ranges, making them suitable for specialized applications like high-end spectroscopy, telecommunications, and laser technology.

What is a holographic grating?

Let’s break down how this works. Imagine two laser beams intersecting at a specific angle. The beams interfere with each other, creating a pattern of bright and dark lines, much like the ripples you see when you drop two pebbles in a pond. These bright and dark areas are called interference fringes. The spacing between these fringes depends on the angle between the laser beams and the wavelength of the light.

Now, imagine that this interference pattern is projected onto a photosensitive material, like a photoresist. This material reacts to light, changing its properties based on the intensity of the light it receives. In areas where the light is bright (the interference fringes), the material undergoes a chemical change, becoming more resistant to etching. In the darker areas between the fringes, the material remains more susceptible to etching.

After exposure to the laser interference pattern, the photosensitive material is processed, typically by etching away the less resistant areas. This etching process creates a series of grooves or lines in the material, with a spacing that corresponds to the spacing of the interference fringes. This etched pattern is the holographic grating.

The unique characteristic of holographic gratings is that the groove shape can be precisely controlled. This control allows for gratings with specific properties, tailored for specific applications. For example, holographic gratings can be designed to diffract light at a particular angle or wavelength, or to create complex patterns of light.

What is ruled grating?

Let’s delve into the fascinating world of ruled gratings.

Imagine a perfectly smooth mirror. Now, picture tiny grooves etched onto that mirror’s surface, like lines drawn in a notebook. These grooves are what make up a ruled grating. The spacing between these grooves is incredibly precise, and it determines how light interacts with the grating. The way these grooves are arranged is crucial, as it determines how the light is dispersed, or spread out. The angle of these grooves impacts the efficiency of the grating, which is a measure of how effectively it reflects light.

The diamond tool used in the ruling process is incredibly sharp and precise. It’s mounted on a ruling engine, which is a highly specialized machine that moves the tool across the surface, meticulously carving out the grooves. The process of making a ruled grating requires a high level of skill and precision, as even the slightest imperfection can affect the performance of the grating.

Ruled gratings play a critical role in various scientific and technological applications. They are used in everything from spectrometers, which are instruments that analyze the spectrum of light, to lasers, which produce highly focused beams of light. These versatile devices are essential for a wide range of research and development efforts, contributing to advancements in fields like astronomy, medicine, and telecommunications.

Which type of grating is the best?

Holographic diffraction gratings are excellent at minimizing stray light, making them a top choice for applications where clear images are essential. While they are fantastic at blocking unwanted light, they tend to have a slightly lower efficiency compared to other grating types.

Transmission gratings are another popular choice. They’re made by creating a repeating pattern of lines on a transparent material. Think of it like a tiny, intricate fence on a glass slide. When light shines through this grating, it gets diffracted, or bent, creating a spectrum of colors.

Now, let’s dive a bit deeper into the world of holographic diffraction gratings:

These gratings are made using a laser interference technique. Imagine you have two lasers pointing at each other. Where their beams overlap, you get a pattern of light and dark areas. This pattern is recorded onto a photosensitive material, creating the grating.

This process allows for the creation of gratings with very fine features, resulting in excellent angular resolution and low stray light. This means you can separate wavelengths of light very precisely, and you won’t have much unwanted light interfering with your measurements.

However, the downside is that they can be less efficient than ruled gratings. This means that they may not be able to direct as much of the light onto your detector, resulting in weaker signals.

So, when choosing between holographic diffraction gratings and transmission gratings, it’s important to consider what you need. If you’re working with faint light sources or need to minimize stray light, holographic gratings are likely the better choice. If you need high efficiency and don’t mind a little bit of stray light, then a transmission grating may be a better fit.

Which grating is preferred?

Transmission gratings shine when it comes to OEM applications. They’re often preferred due to their efficiency and versatility. While reflection gratings are certainly valuable, transmission gratings can offer a more flexible solution for many applications.

But, it’s important to remember that choosing between transmission and reflection gratings isn’t a one-size-fits-all decision. There’s more to consider than just how the light interacts with the grating. Let’s dive into the reasons why transmission gratings often take the lead in many situations.

Transmission gratings excel in several ways:

Efficiency:Transmission gratings are designed to transmit the majority of the incident light, which means you get a lot of usable light coming out on the other side. This is especially beneficial when you need strong signals or are working with weak light sources.

Versatility: Transmission gratings are often easier to integrate into optical systems. They can be incorporated into different optical setups and designs more easily than reflection gratings, which can be more challenging to mount and align.

Cost:Transmission gratings can be more cost-effective than reflection gratings in some cases, making them a good choice for applications where budget is a key factor.

However, reflection gratings do have their own advantages, particularly when you need:

High spectral resolution:Reflection gratings can be designed to achieve very high spectral resolution, making them ideal for applications where precise measurements of wavelengths are crucial.

Durability:Reflection gratings are often more durable than transmission gratings and can withstand harsh environments better.

Ultimately, the choice between transmission and reflection gratings depends on the specific needs of your application. Carefully considering the requirements for your project will help you make the best decision for your optical setup.

What are the two types of diffraction gratings?

Ruled gratings are the traditional type. Imagine a tiny, precise ruler with super-fine grooves etched into it. That’s essentially what a ruled grating is! A special machine called a ruling engine uses a diamond-tipped tool to carve these grooves onto a coated substrate, usually glass with a reflective layer. These grooves act like tiny mirrors that reflect light, and because of how they’re arranged, the light splits into its different wavelengths, creating a rainbow effect.

Holographic gratings are made using a different, more modern technique. Instead of physically carving grooves, they use interference patterns created by laser beams to create the grating. This process is more precise and can create gratings with much finer lines, resulting in higher resolution. Imagine creating a microscopic ruler with lasers! Holographic gratings are often preferred for scientific instruments and applications where high precision and efficiency are essential.

The type of grating used depends on the specific application. Ruled gratings are often used in applications requiring high efficiency, while holographic gratings excel in applications demanding high resolution.

What is the benefit of holographic?

But that’s not all. Holography is super useful for a bunch of things, like:

Entertainment: Imagine watching movies or playing video games with holographic characters that seem real!

Research: Scientists can use holography to study tiny things like cells and molecules in incredible detail.

Security: Holography can help keep things safe by making it really hard to copy important documents or products.

Data Storage: Holography can store a ton of information in a small space, which is great for things like storing medical records or backing up computers.

How does Holography work?

Holography uses lasers to record the light scattered from an object, and then recreates that light to form a 3D image. It’s like taking a picture of light itself! This lets you see the object from different angles and even move around it.

Holography is still pretty new, but it has the potential to change a lot of things in the future. It’s a truly exciting field!

Why is it called holographic?

Think of it this way: a photograph captures a flat image, like a snapshot of a person. But a hologram captures the light from every angle of the object, like you were actually there! That’s why it feels so realistic. You can see the object from different angles and even see behind it, giving it a three-dimensional effect.

This “whole writing” is what makes holograms so special. They capture the object’s light field, which is like a blueprint of the object’s entire form and texture. It’s like taking a 3D photo that captures all the details, not just one flat perspective. That’s why holograms can look so real, like the object is right there in front of you.

See more here: What Is A Holographic Grating? | Ruled Grating Vs Holographic Grating

What is the difference between ruled and holographic gratings?

Ruled gratings get their grooves from a mechanical process. Imagine a tiny, super-precise tool carefully cutting into the surface of the grating. This method is a bit like engraving, but on a much smaller scale.

Holographic gratings, on the other hand, are made using a super cool optical technique. It’s like creating a pattern of light and dark areas using interference. The grating is exposed to two beams of laser light, and the interference pattern of these beams creates the grooves.

Think of it like this: Imagine you have two waves in a pond. Where the crests of the waves meet, the water is higher, and where the troughs meet, the water is lower. It’s like creating a pattern of hills and valleys in the water. Holographic gratings work in a similar way, but instead of water waves, we’re using light waves to create the groove pattern.

What’s the big difference? Ruled gratings have a more uniform groove spacing, which means they can be incredibly precise. Holographic gratings, however, can create grooves with more complex shapes and patterns, leading to some unique optical properties.

To put it simply: Ruled gratings are like a meticulously carved sculpture, while holographic gratings are like a beautiful, intricate tapestry woven from light!

How efficient is a holographic grating?

Let’s break down what this means. Efficiency in a grating refers to how much of the incoming light is diffracted into the desired order. A higher efficiency means more light is used effectively.

The 1800 g/mm refers to the groove density of the grating. This number indicates how many grooves are present per millimeter of the grating’s surface. A higher groove density generally leads to better resolution and smaller spectral features.

500 nm refers to the wavelength of light. This is in the visible part of the electromagnetic spectrum. The fact that a holographic grating can achieve the same efficiency as a blazed, ruled grating at 500 nm is a testament to its effectiveness in this wavelength range.

The sawtooth profile is the shape of the grooves on the grating. This specific shape, peaked near 240 nm, is particularly useful for UV applications. The peak near 240 nm means that the grating is optimized to efficiently diffract light at this wavelength, which is important for applications like UV spectroscopy and UV lithography.

In addition to efficiency, this sawtooth profile also helps to minimize stray light. Stray light is unwanted light that gets scattered or reflected within the optical system. A sawtooth profile helps to direct the light more effectively, reducing the amount of stray light. This makes the holographic grating an ideal choice for applications where high signal-to-noise ratios are crucial.

What is a holographic diffraction grating?

A holographic diffraction grating is a special kind of grating that’s created using a holographic process. After it’s made, it’s coated with a reflective material. This coating is usually aluminum, enhanced aluminum, silver, or gold.

Because holographic gratings are made using lasers, they are incredibly precise. This high precision means they don’t have any periodic errors or imperfections like ruled gratings. This leads to a couple of important benefits:

Lower stray light: Stray light is basically unwanted light that can interfere with your measurements. Holographic gratings produce much less stray light than ruled gratings, leading to clearer and more accurate results.

No ghosting effects: Ghosting effects are false images that can appear in your measurements. Holographic gratings are free of ghosting, providing even more accurate and reliable data.

Why are Holographic Gratings So Precise?

Think of a holographic diffraction grating as a super-fine, super-accurate ruler. Imagine you need to measure a very small object, like a tiny grain of sand. If your ruler is made with a standard, mechanical process, it might have little imperfections or gaps. These tiny errors could make your measurements inaccurate.

A holographic diffraction grating is like a ruler made using a laser. Lasers are incredibly precise, so the grating has a very high degree of accuracy. This is similar to how a laser can be used to measure distances with extremely high accuracy.

Since the holographic grating is made with a laser, its lines are all perfectly spaced and uniform, resulting in a much more accurate and consistent performance compared to a ruled grating. This high precision is a major advantage in applications that require the most accurate measurements, like scientific research and precision instruments.

What is a holographic concave grating?

You might be wondering, “What’s a holographic concave grating?” Well, it’s a type of diffraction grating that uses a holographic process to create the grating lines. This process allows for the creation of gratings with lower f-numbers, which is a big deal when it comes to performance.

Why are lower f-numbers so important? Lower f-numbers mean that the grating can focus light more tightly, which leads to higher resolution and better signal-to-noise ratio. Think of it like this: Imagine trying to take a picture with a blurry lens. You wouldn’t get a very good picture, right? The same principle applies to holographic concave gratings. A lower f-number is like having a sharper lens, giving you a clearer and more detailed image.

So, why are holographic gratings better than ruled gratings? Well, they’re simply more efficient at diffracting light. A blazed holographic grating can redirect almost all of the incoming light into a single diffraction order, while ruled gratings tend to scatter light more widely. This means that a blazed holographic grating will give you a brighter, more focused signal.

Imagine you’re trying to find a specific star in the night sky. If you use a telescope with a ruled grating, it’s like trying to find the star through a hazy cloud. You might see it, but it’ll be dim and hard to focus on. However, with a blazed holographic grating, you’ll see that star shining brightly, clear as day.

In short, holographic concave gratings are the way to go if you want the best possible performance from your diffraction grating. They offer higher resolution, better signal-to-noise ratio, and greater efficiency than their ruled counterparts.

See more new information: countrymusicstop.com

Ruled Grating Vs Holographic Grating: Which Is Right For You?

Let’s dive into the world of gratings, those essential tools used in a wide range of scientific and technological applications, from spectroscopy to optical communications. You’ll often hear the terms ruled grating and holographic grating being thrown around. But what’s the difference between them? And which one’s better?

Well, it’s not as simple as choosing between a red or blue shirt. Each type of grating has its own unique characteristics, advantages, and disadvantages. We’ll explore these differences in detail to help you understand when each type is the best choice.

Understanding the Basics: What is a Grating?

Think of a grating as a fancy comb with a whole lot of teeth. Okay, maybe not fancy, but definitely useful! It’s basically a surface with a series of parallel lines, grooves, or slits, etched onto it. These lines are incredibly close together, almost microscopic.

When light shines onto a grating, it interacts with those tiny lines. This interaction causes the light to diffract, which means it bends and spreads out. This diffraction is what gives us the ability to separate light into its different colors (like in a spectrometer) or to create specific patterns of light (like in a laser)

Ruled Grating: The Classic Approach

Imagine carving those lines onto the surface using a sharp tool. That’s how a ruled grating is made, literally ruled onto a surface. It’s like using a giant, ultra-precise ruler to make the tiny lines.

How it’s done:

A diamond tool is used to cut the lines onto a substrate, which can be made of materials like glass, metal, or plastic.

* This process can be incredibly precise, but it’s also very time-consuming.

The ruling engine is a complex machine that controls the diamond tool to create the lines.

Key Features:

High efficiency in diffracting light, meaning it’s very good at splitting light into its different colors.

Good for large-scale production of gratings, so it’s economical.

Durable because of its physical structure.

Can be created with very high groove density, leading to high resolution in spectroscopy and other applications.

Limitations:

Limited flexibility in terms of groove shape and spacing. The ruling process is precise but not as customizable as other methods.

Can have ghost lines, which are unwanted lines that can interfere with the desired diffraction pattern.

Production can be expensive, especially for high-resolution gratings.

Holographic Grating: The Light-Based Method

Holographic gratings are a bit more high-tech. Instead of carving lines, we use light interference to create the pattern. Think of it as taking a photo of the interference pattern created by two beams of light.

How it’s done:

Two coherent beams of laser light are projected onto a photosensitive material.

* The interference of these beams creates a pattern of alternating bright and dark areas.

This pattern is then chemically etched onto the material to create the grating.

Key Features:

High-frequency grooves, enabling high resolution in various applications.

Customizable groove shapes and flexible grating designs are possible, which is a big plus for scientists.

Low ghost lines, meaning a cleaner diffraction pattern without unwanted interference.

Can be produced on curved surfaces, making them ideal for applications like fiber optics and spectrometers.

Limitations:

Lower diffraction efficiency compared to ruled gratings, so they might not be as effective at splitting light.

More expensive to produce due to the complex process and materials involved.

The photosensitive material can be damaged by UV light, limiting their applications in certain environments.

Which One Should You Choose?

Choosing between a ruled and holographic grating depends on your needs.

Here are some scenarios to consider:

If you need high efficiency in splitting light, high durability, and don’t require the flexibility of customizable designs, a ruled grating might be a good choice.

If you need high resolution, customizable groove shapes, and a clean diffraction pattern, a holographic grating is the way to go.

If you’re on a budget, ruled gratings are generally cheaper to produce.

If you need a grating for a specific application, like fiber optics or spectroscopy, either type might be suitable, depending on the specific requirements.

Key Differentiators:

| Feature | Ruled Grating | Holographic Grating |

|————-|—————-|——————-|

| Production Method | Mechanical ruling | Holographic interference |

| Efficiency | Higher | Lower |

| Flexibility | Lower | Higher |

| Ghost Lines | More prone | Less prone |

| Resolution | Typically lower | Typically higher |

| Cost | Lower | Higher |

| Applications | Spectroscopy, lasers, fiber optics | Spectroscopy, lasers, optical communications |

Beyond the Basics: Some Interesting Facts

Did you know that the first ruled gratings were made in the 18th century? They were used to study the spectrum of light, leading to significant discoveries in physics and astronomy.

Holographic gratings are used in many everyday devices, such as CD players and DVD players, where they are responsible for reading the data stored on the discs.

The development of new materials and fabrication techniques is constantly pushing the boundaries of what’s possible with both ruled and holographic gratings.

FAQs:

Q: Can a ruled grating be used for the same applications as a holographic grating?

A: While both are used in similar applications, their specific performance and characteristics can make one more suitable than the other. For example, a ruled grating might be better for applications that require high efficiency, while a holographic grating might be better for those that require high resolution or flexibility in design.

Q: What are the applications of gratings?

A: Gratings are used in a wide variety of applications, including:

Spectroscopy: Analyzing the spectrum of light to identify chemical compounds, study astronomical objects, and more.

Lasers: Creating and manipulating beams of light for a wide range of applications, from medical treatment to optical communications.

Fiber optics: Directing and splitting light in optical fibers for telecommunications and other applications.

Optical metrology: Measuring and calibrating optical systems.

Optical data storage: Reading and writing information on optical media like CDs and DVDs.

Q: Which type of grating is better?

A: There’s no one-size-fits-all answer. The “best” grating depends on your specific needs and application. Consider the factors we discussed, such as efficiency, resolution, flexibility, cost, and durability, when making your decision.

Q: What are some alternative types of gratings?

A: Beyond ruled and holographic gratings, there are other types of gratings with unique properties. These include:

Subwavelength gratings: These gratings have features smaller than the wavelength of light, allowing them to manipulate light in ways not possible with traditional gratings.

Binary gratings: These gratings are designed with only two levels of depth, creating a binary pattern. They are often used in optical communications and displays.

Diffractive optical elements (DOEs): These elements are more complex than gratings and can create a variety of optical effects. They are used in a wide range of applications, including imaging, microscopy, and optical manipulation.

As technology continues to advance, we can expect even more exciting developments in the field of grating technology. From improved fabrication techniques to new materials, the possibilities for applying gratings are endless. Whether you’re a scientist, engineer, or just someone curious about the world around you, understanding the differences between ruled and holographic gratings is a great starting point.

Diffraction Gratings Ruled and Holographic – HORIBA

Classically ruled gratings may be planar or concave and possess grooves, each parallel with the next. Holographic grating grooves may be either parallel or of unequal distribution in order to optimize system performance. Holographic gratings are generated on HORIBA

Differences Between Ruled and Holographic Gratings – Newport

While holographic gratings generally exhibit lower scattered light than early ruled gratings, modern control systems and improved master coatings have led to ruled Newport

What is the difference between holographic and ruled diffraction

Ruled gratings have a sawtooth-shaped groove profile tilted at a specific angle (the blaze angle) that is designed to have maximum efficiency at a specific (blaze) wavelength. Edmund Optics

Ruled Grating vs Holographic Grating – Spectrum Scientific, Inc.

Ruled Grating vs Holographic Grating. Ruled diffraction gratings by the nature of the manufacturing process cannot be produced without defects, which may include periodic Spectrum Scientific, Inc.

Optics Introduction to Diffraction Grating – Thorlabs

ruled grating. Blaze Wavelength: Ruled gratings with a “sawtooth” groove profile have a relatively sharp efficiency peak around their blaze wavelength, while some holographic Thorlabs

All About Diffraction Gratings | Edmund Optics

Ruled vs. Holographic Gratings. Both reflection and transmission gratings can be further broken down into ruled or holographic gratings, which differ in the way that the groove Edmund Optics

Diffraction Gratings: Selection Guidelines | Optics

A holographic grating with 1800 g/mm can have the same efficiency at 500 nm as a blazed, ruled grating. In addition, special processes enable holographic gratings to achieve a sawtooth profile peaked near 240 nm Photonics.com

Diffraction Gratings Tutorial – Thorlabs

Ruled gratings generally have a higher efficiency than holographic gratings. Holographic grating tend to have a lower efficiency but a broader effective wavelength range. The efficiency of ruled Thorlabs

Understanding and selecting diffraction gratings – Acal BFi

Holographic gratings Initial preparation for holographic grating production is similar to that for ruled gratings, but the coating used for a holographic grating is a photosensitive Acal BFi

Spectrum Scientific – Diffraction Gratings Introduction – SSI Optics

There are typically two different types of diffraction grating – the ruled grating and the holographic grating. ruled diffraction grating is produced by a ruling engine that cuts Spectrum Scientific, Inc.

Diffraction Gratings 101: Types And Applications

Diffraction Grating

How Does A Grating Work? | Raman For Beginners | Optical Gratings

Diffraction Grating | Light Waves | Physics | Khan Academy

Hyperspectral Microscope: Prism Or Grating?

Link to this article: ruled grating vs holographic grating.

See more articles in the same category here: blog https://countrymusicstop.com/wiki