What is the NPSH requirement for a progressive cavity pump?

Why is this important? NPSH is a crucial parameter that determines a pump’s ability to operate without cavitation. Cavitation occurs when the pressure at the pump’s suction inlet drops below the vapor pressure of the liquid being pumped. This causes vapor bubbles to form, which can then collapse violently, damaging the pump impeller.

Progressive cavity pumps have a unique design that helps to minimize the risk of cavitation. They use a rotating screw-like rotor that meshes with a stationary stator, creating a series of cavities that trap and transport the fluid. The low internal velocity within these cavities contributes to a lower NPSH requirement compared to centrifugal pumps.

Centrifugal pumps rely on the centrifugal force generated by a rotating impeller to move the fluid. They typically require higher NPSH to prevent cavitation, as the impeller speed and flow velocity are much higher. This makes progressive cavity pumps an excellent choice for applications where suction conditions are challenging, such as pumping from low-pressure tanks or handling fluids with high vapor pressure.

Let’s break it down:

Progressive cavity pumps can handle suction pressures as low as 28 inches of mercury (Hg), whereas centrifugal pumps often struggle at those levels. This means you can use a progressive cavity pump for applications where a centrifugal pump wouldn’t be suitable.

Progressive cavity pumps have a lower internal velocity, which contributes to their ability to operate with lower NPSH.

Lower NPSH allows for a more efficient and reliable pumping process, especially in situations with limited suction pressure or high vapor pressures.

In summary, progressive cavity pumps excel in situations where you have limited suction pressure and require reliable, efficient operation. Their low NPSH requirement makes them ideal for pumping difficult fluids or handling applications where traditional centrifugal pumps would struggle.

Can you cavitate a progressive cavity pump?

Let’s break down why this happens. Cavitation occurs when liquid pressure drops below its vapor pressure. This creates vapor bubbles that can grow and collapse violently. This collapse creates shock waves that can damage pump components.

Progressive cavity pumps, however, are particularly well-suited to handle this phenomenon because of their unique design. The stator, made of a flexible elastomer material, provides a cushioning effect. When a cavitation bubble collapses, the stator absorbs the energy of the shock wave, preventing it from damaging the pump. Think of it like a flexible rubber cushion absorbing the impact of a dropped object.

Moreover, the rotor-stator system of progressive cavity pumps is designed with a tight clearance between the moving parts. This design helps minimize the formation of cavitation bubbles in the first place.

However, it is important to note that while progressive cavity pumps are generally more resistant to cavitation, they are not completely immune. If cavitation is severe enough, it can still cause damage to the pump over time. Therefore, it’s essential to operate progressive cavity pumps within their recommended operating conditions to minimize the risk of cavitation and ensure their longevity.

How is NPSH related to cavitation in pumps?

Think of it this way: Imagine you’re sucking up a milkshake through a straw. If you don’t have enough suction power, the milkshake won’t flow smoothly. Instead, you’ll end up with air bubbles and a sputtering mess.

This is exactly what happens in a pump when the NPSH is too low. The pressure on the suction side of the pump is not high enough to overcome the vapor pressure of the liquid. This causes the liquid to vaporize, creating tiny bubbles called cavities. These cavities then collapse violently as they enter the high-pressure area of the pump, creating shock waves that can erode the pump’s impeller and casing.

Here’s why NPSH is so important for avoiding cavitation:

NPSH is directly related to the pressure available to overcome the vapor pressure of the fluid. If the NPSH is too low, the pressure is insufficient to prevent the liquid from vaporizing.

NPSH is also influenced by factors like fluid temperature, altitude, and the pump’s design. These factors can all affect the amount of pressure needed to prevent cavitation.

So, how do you make sure your pump has enough NPSH?

Check the pump’s manufacturer’s specifications. They will provide a required NPSH value for the pump.

Measure the actual NPSH available at your installation. This can be done with a pressure gauge or by using a calculation.

Ensure that the available NPSH is greater than the required NPSH. This will ensure that the pump has enough pressure to prevent cavitation.

By understanding and managing NPSH, you can prevent cavitation and extend the life of your pump.

What are the limitations of a progressive cavity pump?

Dry running occurs when the pump operates without sufficient lubrication, which can cause increased wear on the rotor and stator. This is because the positive displacement nature of these pumps means that the fluid being pumped acts as both the lubricant and the cooling agent. Without adequate fluid, the pump’s components can overheat and wear down quickly.

To prevent dry running, it’s essential to ensure that the pump is always primed with fluid before starting it. You can also consider using a lubricant injection system to add extra lubrication.

Another limitation of progressive cavity pumps is their limited pumping speed compared to other types of pumps, such as multi-screw pumps. This means that they are not ideal for high flow rate applications where a large volume of fluid needs to be moved quickly.

Progressive cavity pumps are best suited for applications that require a relatively low flow rate, a high degree of viscosity, and the ability to handle abrasive or corrosive fluids. They are commonly used in industries like mining, oil and gas, and food processing. While they have some limitations, these pumps offer a unique set of advantages that make them a valuable tool in various applications.

Do progressive cavity pumps need to be primed?

So, do progressive cavity pumps need to be primed? The answer is no.

Here’s why:

How Progressive Cavity Pumps Work: Progressive cavity pumps work by using a rotating screw inside a stator. The screw creates a series of cavities that trap the fluid and move it along the pump. The unique design of the pump allows it to handle a wide range of viscosities and even handle fluids with suspended solids.

Self-Priming Mechanism: The self-priming ability of progressive cavity pumps stems from the fact that they create a vacuum within the pump housing when they start operating. This vacuum draws the fluid into the pump, allowing it to begin pumping without needing external assistance.

Advantages of Self-Priming: The self-priming nature of progressive cavity pumps offers several advantages:

No Need for Priming Systems: You don’t need to install complex priming systems like you would with other pump types. This simplifies the installation and operation of the pump.

Reduced Maintenance: Less reliance on external systems means less maintenance and fewer potential issues.

Greater Efficiency: Since the pump can start working immediately, it’s more efficient and saves you energy.

Versatility: Self-priming allows you to use progressive cavity pumps in a wider range of applications, including those where the fluid level may fluctuate.

Overall, progressive cavity pumps offer a reliable, efficient, and convenient solution for handling challenging fluids. Their self-priming capability makes them a top choice in many industrial settings.

Is a progressive cavity pump a positive displacement pump?

These pumps work by trapping a fixed volume of fluid in a series of cavities created by the interaction of a rotor and a stator. As the rotor turns, these cavities move along the pump, pushing the fluid forward. This constant, controlled movement of fluid is what makes them positive displacement pumps.

Let’s break down why that is. Positive displacement pumps are known for their ability to deliver a precise volume of fluid with each revolution of the pump. They do this by trapping a fixed volume of fluid and then forcing it out. This is in contrast to centrifugal pumps, which rely on the velocity of the fluid to generate pressure.

Progressive cavity pumps are great for handling a variety of fluids, including thick, viscous, abrasive, and shear-sensitive fluids. This is because the rotating elements don’t create a lot of shear stress, which can damage delicate fluids. They are often used in industries like food processing, pharmaceuticals, and wastewater treatment.

Let me tell you a little more about how progressive cavity pumps work.

The heart of the pump is the rotor, which is a helical screw with a series of lobes or cavities. This rotor sits inside a stationary stator, which has a similar helical shape, but with internal cavities that are slightly larger than the rotor cavities.

As the rotor turns, it creates a series of pockets between the rotor and stator. These pockets are filled with fluid, and as they move along the pump, they force the fluid forward.

The key to the progressive cavity pump’s ability to handle different types of fluids is the design of the rotor and stator. These components are precisely engineered to create a smooth, continuous flow of fluid, minimizing the potential for shear forces that can damage delicate fluids.

The progressive cavity pump’s ability to move a fixed volume of fluid with each revolution also makes them highly efficient. They are able to provide a consistent flow rate, even at high pressures, and can be used to move fluids over long distances.

Do you have any other questions about progressive cavity pumps or positive displacement pumps? I’m happy to explain more.

What happens if NPSH is too high?

Think of it like this: NPSH is essentially a measure of how much pressure your pump has to overcome to draw liquid from the suction side. So, a high NPSH simply means there’s a lot of pressure available for the pump to work with.

Now, while a high NPSH doesn’t pose any immediate risks, it can mean you’ve over-engineered your system. This could lead to unnecessary costs and energy consumption. For instance, if your pump is designed to handle a large flow rate, but you’re only using a small portion of its capacity, you’re effectively wasting energy.

Here’s a scenario to illustrate the point: imagine you’re driving a powerful sports car on a quiet residential street. You might have a lot of power at your disposal, but it’s unlikely you’ll need it to get around. Similarly, if your pump has a high NPSH but the application doesn’t require it, you’re essentially carrying around unnecessary horsepower.

Here are some scenarios where high NPSH might be beneficial:

Variable Flow Rate Applications: If your system needs to handle a wide range of flow rates, a high NPSH provides flexibility. The pump will operate efficiently even when the flow rate is low.

High Altitude Operations: At high altitudes, atmospheric pressure is lower, and a higher NPSH might be necessary to ensure the pump can draw fluid effectively.

In essence, high NPSH is not a problem in itself. However, it’s essential to ensure that the NPSH you’ve designed for is appropriate for your specific application. If you find your NPSH is significantly higher than necessary, consider re-evaluating your system design to optimize efficiency.

What happens if NPSH is less than Npshr?

NPSH stands for Net Positive Suction Head. It’s basically the amount of pressure available at the pump’s suction inlet, ensuring a smooth flow of liquid into the pump. NPSHr, on the other hand, is the Net Positive Suction Head Required by the pump to operate efficiently.

Think of it like this: NPSH is the “pressure you have,” and NPSHr is the “pressure you need”. If NPSH is less than NPSHr, it means the pump isn’t getting enough pressure to work properly, which can lead to some problems.

When NPSH is less than NPSHr, the liquid inside the pump can start to vaporize, creating bubbles. These bubbles are called cavitation. Cavitation can cause a lot of issues:

Reduced Flow: The bubbles take up space in the liquid, which reduces the flow rate through the pump.

Noise and Vibration:Cavitation creates a lot of noise and vibration, which can damage the pump and surrounding equipment.

Erosion: The collapsing bubbles can erode the pump’s internal parts, leading to wear and tear.

In short, cavitation is a serious problem that can lead to reduced efficiency, damage, and even pump failure. So, it’s really important to make sure that NPSH is always greater than NPSHr.

How to avoid cavitation?

Here are a few tips:

Increase Suction Pressure: You can increase the suction pressure by using a larger suction pipe or by using a booster pump.

Reduce Suction Head: Lowering the suction head can help by reducing the amount of pressure needed to lift the liquid.

Check for Leaks: Leaks in the suction line can reduce NPSH, so it’s important to check for leaks and fix them.

Use the Right Pump: Choosing the right pump for the application is key. You need to make sure that the pump can handle the required flow rate and head at the specified suction pressure.

By following these tips, you can help prevent cavitation and ensure that your pump operates smoothly and efficiently.

See more here: Can You Cavitate A Progressive Cavity Pump? | Npsh Required For Progressive Cavity Pump

What is NPSH in pumping?

Think of it like this: Imagine a straw in a glass of water. You suck on the straw and the water rises. If you suck too hard, you’ll create a vacuum at the top of the straw, and the water will start to boil. This is essentially cavitation.

NPSHR is a crucial factor in pump design and operation. It’s measured in feet or meters of head and depends on the pump’s specific design and operating conditions. You can think of it as the pump’s “appetite” for pressure.

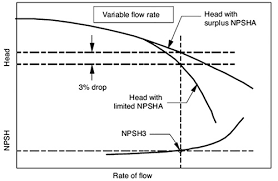

The amount of pressure required depends on various factors, including the liquid’s specific gravity (how heavy it is). NPSHR is defined as the Net Positive Suction Head at which the pump’s total head has decreased by three percent (3%) due to low suction head and resultant cavitation within the pump.

In simple terms, if the NPSHA (Net Positive Suction Head Available) is less than the NPSHR, cavitation can occur, leading to pump damage. To avoid this, it’s essential to ensure that the NPSHA always exceeds the NPSHR.

To make sure you have enough NPSHA to prevent cavitation, you need to consider factors like:

Pump speed: A higher speed usually requires a higher NPSHR.

Liquid viscosity: More viscous liquids require a higher NPSHR.

Vapor pressure: Liquids with a higher vapor pressure require a higher NPSHR.

Temperature: Higher temperatures increase vapor pressure, leading to a higher NPSHR.

By carefully considering these factors, you can ensure your pumps operate efficiently and effectively while avoiding costly damage due to cavitation.

What is NPSH required?

The NPSH required ( NPSHr ) is usually provided by the pump manufacturer. You’ll typically find this value on the pump’s performance curves. It’s important to understand that NPSHr and NPSH3 are essentially the same thing.

Here’s a bit more about NPSHr and why it’s so important:

Imagine a pump trying to suck water up a straw. If the straw is too long, the water might not reach the pump. This is similar to what happens with NPSH. If the pressure at the pump’s suction is too low, the liquid can vaporize before it reaches the pump. This is called cavitation, and it’s a serious problem.

Cavitation can damage your pump, reduce efficiency, and even cause the pump to fail. That’s why NPSHr is so important. It tells you how much pressure you need at the pump’s suction to avoid cavitation.

To prevent cavitation, you need to make sure the NPSH available ( NPSHa ) is greater than the NPSHr. NPSHa is the pressure at the pump’s suction that you actually have.

To calculate NPSHa, you’ll need to consider factors like the height of the liquid source, the pressure in the liquid source, and the friction losses in the suction piping. If your NPSHa is less than your NPSHr, you’ll need to take steps to increase the pressure at the pump’s suction.

This could involve using a larger suction pipe, lowering the liquid level in the tank, or installing a booster pump.

Understanding NPSHr and how to calculate NPSHa is crucial for ensuring your pump operates smoothly and efficiently.

What is the meaning of NPSHR/NPSH3 in pumps?

The Hydraulic Institute (HI) sets the standard for how pump manufacturers measure NPSHR, which stands for Net Positive Suction Head Required. It’s basically the minimum pressure a pump needs at the suction point to operate properly without cavitation. Think of it like this: the pump needs a certain amount of “push” to get the liquid moving.

Now, you might hear people talking about NPSH3. It’s a newer term that means the same thing as NPSHR. The reason for the change? Well, NPSHR can be a little misleading. It sounds like it’s related to the NPSHA, which is the Net Positive Suction Head Available, but it’s actually not.

NPSH3 is a more precise term because it emphasizes that the number represents a specific operating condition: a 3 percent head drop at the impeller.

So, why do we need NPSH3? It’s all about avoiding cavitation, which happens when the pressure drops too low at the suction side of the pump. This causes bubbles to form in the liquid, which can damage the pump. That’s why HI recommends an NPSHA/NPSHR margin of 1.1 to 2.5. This margin ensures that there’s enough pressure at the suction side to prevent cavitation.

Let me explain the NPSHA/NPSHR margin a little better. The NPSHA is the actual head available at the suction side of the pump. NPSHR is the minimum head needed for the pump to operate properly without cavitation. The NPSHA/NPSHR margin is the difference between these two values.

Think of it like a safety buffer. By having a margin, you’re making sure that even if the NPSHA drops slightly, you’re still operating safely above the NPSHR threshold and avoiding cavitation.

If you’re interested in learning more about the specifics of NPSHR and NPSH3, check out the Hydraulic Institute website. They have a wealth of information on pump design and operation.

In short, NPSHR and NPSH3 are different ways of describing the same thing: the minimum pressure required at the suction side of a pump to prevent cavitation. They’re both important concepts to understand when selecting and operating pumps.

Why should you choose a progressing cavity Mono pump?

Progressing cavity mono pumps are a great choice for many applications, and one of their key advantages is their great suction lift capabilities. This means they can handle challenging suction conditions better than other pump types. Let’s break down why this is a big deal:

Net Positive Suction Head (NPSH)

You might have heard the term NPSH thrown around, but what does it really mean? Think of NPSH as the minimum pressure required at the pump inlet to prevent cavitation. Cavitation is a serious issue that can damage your pump, so you want to make sure your pump has enough NPSH to operate safely and efficiently.

Progressing Cavity Mono Pumps and NPSH

The cool thing about progressing cavity mono pumps is their design allows them to operate with a low NPSH. This means they can handle situations where the suction pressure is lower than what other pumps might require. This makes them perfect for applications where:

The liquid source is located far below the pump. This might be a common problem in industrial settings with deep tanks or underground wells.

The liquid contains gases or vapors. These can reduce the available suction pressure and cause problems for other pumps.

The piping system is long or has many bends. This can also create pressure drops that make it difficult for other pumps to operate efficiently.

Example: Think of your car’s engine

Imagine your car’s engine as a pump. It needs a certain amount of air to run smoothly. If the air intake is blocked or restricted, your car will struggle to start or run properly. Similarly, a pump needs a certain amount of pressure at the inlet to operate efficiently. If the pressure is too low, the pump can experience cavitation, which is like the air intake being blocked in your car. Progressing Cavity Mono Pumps are designed to handle these challenging conditions, making them a reliable choice for many applications.

See more new information: countrymusicstop.com

Npsh Required For Progressive Cavity Pump | What Is The Npsh Requirement For A Progressive Cavity Pump?

Alright, let’s dive into the world of NPSH (Net Positive Suction Head) and how it impacts the performance of your progressive cavity pump. I know it might sound a bit technical, but trust me, understanding this is key to keeping your pump running smoothly and efficiently.

Think of NPSH as the amount of energy available to push the liquid into the pump. It’s like the fuel your pump needs to operate. NPSH is calculated by comparing the absolute pressure at the pump suction to the vapor pressure of the liquid being pumped.

NPSH is measured in feet of head or meters of head. Basically, it tells you how much pressure you have available at the suction side of the pump to overcome the forces that want to cause cavitation.

Why is NPSH Crucial?

Cavitation is a big problem you want to avoid. It happens when the liquid pressure drops below the liquid’s vapor pressure. This creates vapor bubbles in the liquid, which collapse as they reach a high-pressure area. The collapsing bubbles create shockwaves, which can damage your pump over time.

Here’s the thing about progressive cavity pumps: they’re known for their ability to handle abrasive, viscous, and even shear-sensitive fluids. But they are also susceptible to cavitation if you don’t pay attention to NPSH.

How to Calculate NPSH

To make sure your progressive cavity pump is running safely, you need to know the NPSH required for the pump and the NPSH available at the suction.

Here’s the breakdown:

NPSH Required: This is the minimum amount of NPSH the pump needs to operate without cavitation. You can find this information in the pump manufacturer’s documentation or by contacting them directly.

NPSH Available: This is the actual NPSH at the suction of the pump. It depends on factors like the height of the liquid level in the tank, the atmospheric pressure, and the friction losses in the suction piping. You can calculate NPSH available using the following formula:

NPSHA = (Patm / ρg) + (Hs / ρg) – (Hv / ρg) – (Hf / ρg)

Where:

NPSHA: Net Positive Suction Head Available (feet of head)

Patm: Atmospheric Pressure (psia)

ρ: Density of the liquid (lbm/ft^3)

g: Acceleration due to gravity (32.2 ft/s^2)

Hs: Static head (feet of head) – The height of the liquid level above the pump centerline.

Hv: Vapor pressure of the liquid (psia)

Hf: Friction losses in the suction piping (feet of head) – This includes losses due to pipe fittings, valves, and bends.

Understanding the Components of NPSHA

Let’s break down the NPSHA formula in a way that’s easy to understand:

(Patm / ρg): This is the atmospheric pressure head. It’s the pressure from the surrounding air at your location.

(Hs / ρg): This is the static head, which basically means the head due to the height of the liquid above the pump.

(Hv / ρg): This is the vapor pressure head, which basically means the pressure at which the liquid starts to vaporize.

(Hf / ρg): This is the friction head, which is a measure of the pressure lost due to friction in the suction piping.

Factors Affecting NPSH Requirements

The NPSH required for a progressive cavity pump can be influenced by several factors, including:

Fluid Properties: The viscosity and vapor pressure of the fluid play a crucial role. More viscous fluids and liquids with lower vapor pressures require higher NPSH.

Pump Speed: Higher pump speeds mean higher flow rates, which can lead to lower pressure at the suction and require more NPSH.

Pump Design: The design of the pump’s impeller, volute, and suction piping can all affect the NPSH required.

Operating Conditions: The elevation of the pump and the ambient temperature can also affect NPSH requirements.

Consequences of Insufficient NPSH

Let’s be clear, running a pump with insufficient NPSH can have some serious consequences:

Cavitation: This is the most common issue. It leads to erosion of pump components, reduced efficiency, and noisy operation.

Reduced Flow Rate: Insufficient NPSH can result in a lower flow rate than expected.

Pump Failure: In extreme cases, insufficient NPSH can lead to pump failure.

How to Ensure Adequate NPSH

Here’s what you can do to make sure your progressive cavity pump has enough NPSH:

Choose the Right Pump: Select a pump with a NPSH rating that is suitable for your application.

Optimize the Suction Piping: Keep the suction piping as short and straight as possible to minimize friction losses.

Reduce Suction Head: Lower the suction head by positioning the pump as close to the liquid level as possible.

Use a Booster Pump: If the NPSH available is insufficient, you can use a booster pump to increase the pressure at the suction.

Monitor NPSH: Regularly check the NPSH at the pump suction to ensure it remains within the required range.

Tips for Avoiding Cavitation in Progressive Cavity Pumps

Here are some specific tips for avoiding cavitation in your progressive cavity pump:

Use a Larger Suction Line: This helps to reduce the velocity of the fluid in the suction line, which can help to minimize pressure drops.

Ensure a Positive Static Head: Make sure the liquid level in the tank is above the pump centerline.

Avoid Sharp Bends: Use smooth transitions in the suction piping to minimize friction losses.

Use a Strainer: This helps to prevent debris from entering the pump and obstructing flow.

Use a Check Valve: A check valve in the suction line can help to prevent backflow and maintain a positive pressure at the suction.

Consider a Larger Pump: If you’re struggling with NPSH, a larger pump might be necessary to handle the flow rate with a lower suction head.

FAQs About NPSH

Here are some frequently asked questions about NPSH:

1. What happens if my progressive cavity pump is cavitating?

If your progressive cavity pump is cavitating, you’ll hear a rattling or knocking noise. You might also see a decrease in flow rate or an increase in vibration.

2. How often should I check the NPSH of my pump?

You should check the NPSH of your progressive cavity pump regularly, especially if there are changes in the operating conditions, like a drop in the liquid level or a change in the viscosity of the fluid being pumped.

3. What are the best ways to improve NPSH?

There are a few ways to improve NPSH:

Reduce friction losses in the suction piping: This can be done by using larger diameter pipe, eliminating sharp bends, and minimizing the number of fittings.

Increase the static head: This can be done by raising the liquid level in the tank or by using a booster pump.

4. What are the consequences of low NPSH?

Low NPSH can lead to cavitation, which can damage the pump and reduce its efficiency. It can also lead to a decrease in flow rate and, in extreme cases, pump failure.

5. How can I prevent cavitation in my progressive cavity pump?

You can prevent cavitation by ensuring adequate NPSH available, optimizing the suction piping, and using a strainer to prevent debris from entering the pump.

6. What is the difference between NPSH required and NPSH available?

NPSH required is the minimum NPSH needed for the pump to operate without cavitation. NPSH available is the actual NPSH at the suction of the pump. You want to make sure that the NPSH available is greater than the NPSH required.

7. How can I calculate NPSH?

You can calculate NPSH using the formula mentioned above:

NPSHA = (Patm / ρg) + (Hs / ρg) – (Hv / ρg) – (Hf / ρg)

8. What are some of the factors that affect NPSH?

Several factors can affect NPSH, including the fluid properties, the pump speed, the pump design, and the operating conditions.

9. What is the significance of NPSH?

NPSH is significant because it is a key parameter that determines whether a pump will cavitate. Cavitation can damage the pump and reduce its efficiency. Understanding NPSH is critical to ensuring your pump operates reliably and efficiently.

10. How do I choose the right pump based on NPSH?

When choosing a pump, you need to consider the NPSH required by the pump and the NPSH available at the suction. Make sure the NPSH available is greater than the NPSH required.

11. What are some tips for troubleshooting cavitation in a progressive cavity pump?

Here are some tips for troubleshooting cavitation in a progressive cavity pump:

Check the NPSH: Make sure the NPSH available is greater than the NPSH required.

Check the suction piping: Make sure the suction piping is free of obstructions and that there are no sharp bends.

Check the pump speed: Ensure the pump speed is within the recommended range.

12. What are some examples of progressive cavity pumps that require high NPSH?

Some examples of progressive cavity pumps that require high NPSH include pumps used for pumping viscous fluids, high-pressure applications, or applications where there is a large suction head.

13. What are some examples of progressive cavity pumps that require low NPSH?

Some examples of progressive cavity pumps that require low NPSH include pumps used for pumping low-viscosity fluids, low-pressure applications, or applications where there is a small suction head.

By understanding the importance of NPSH and implementing the tips provided, you can ensure the longevity and optimal performance of your progressive cavity pump.

NPSHR for pregressive cavity pumps – Pump engineering – Eng-Tips

NPSHR is defined as the NPSH at which the pump total head has decreased by three percent (3%) due to low suction head and resultant cavitation within the pump. This number is shown on your pump curve, but it is going to be too low if you are Eng-Tips

NPSHR Standard – Rotating Right

Applying the NPSHR Standard to Progressing Cavity Pumps Take NPSHR values into consideration to ensure proper continuous operation. By Michael Dillon and Klaus Vüllings As reference level, the horizontal level will be defined as – in devia- tion from the definition for rotary pumps (e.g., ISO 2548 or DIN 24260 – passing through the center of … rotatingright.com

How Do I Know if a Progressing Cavity Pump Is the

Unlike a centrifugal pump that “throws” the fluid away from the impeller vanes, a progressive cavity pump enables the fluid to move from one cavity to the next, “pushing” the fluid forward. In return, this Estabrook

Progressive Cavity Pump Guide – Castle Pumps

Great suction lift capabilities – The progressing cavity mono pump design benefits from a low Net Positive Suction Head (LPSH), which means that less inlet pressure is required for the pump to operate at Castle Pumps

UNDERSTANDING NPSH & Cavitation – Pumps & Systems

Definition. t Positive Suction Head (NPSH). NPSH is the diference between suction pressure . gnation) and vapo. NPSH = P – P. s vap. Where: NPSH = NPSH available from the system, at the pump inlet, with the pump running. P = Stagnation suction. s. pressure, at the pump inlet, with the pump running. Pumps & Systems

A Quick Guide To Progressive Cavity Pumps And How To Make

When suction conditions aren’t great, a progressive cavity pump needs a much lower Net Positive Suction Head (NPSH) to a centrifugal pump. This is because its internal pump velocity is lower. Vissers Sales Corp.

Pump Npsh Basics

Pump Cavitation And Net Positive Suction Head

Closed Drain Semi-Submerged Pump – Npsha Calculation [Progressive Cavity Pump]

How A Progressive Cavity Pump Works

Npsh Required Of A Pump – Pump Curve / Applied Fluid Dynamics – Class 051

Link to this article: npsh required for progressive cavity pump.

See more articles in the same category here: blog https://countrymusicstop.com/wiki